12/08/2022

Rhodosporidium toruloides Engineered to Produce Triacetic Acid Lactone from Sorghum

One-pot biomass deconstruction and valorization advances cost-effectiveness

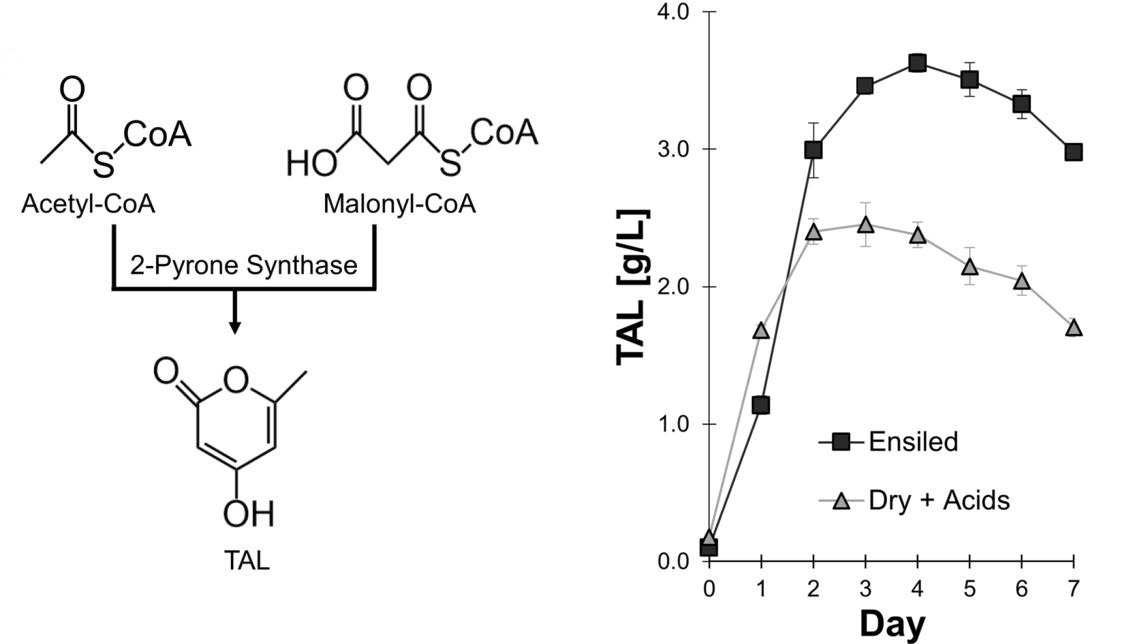

Triacetic acid lactone (TAL) production in the engineered yeast Rhodosporidium toruloides. Schematic of TAL production using the 2-pyrone synthase gene randomly integrated into the R. toruloides genome (left). One-pot pretreatment and saccharification produced hydrolysates from either ensiled sorghum or dry sorghum; TAL titers were higher in the R. toruloides fermentation of the ensiled hydrolysate (right).

[Reprinted under a Creative Commons license (CC BY) from Otoupal et al. 2022. DOI:10.1186/s12934-022-01977-0]

The Science

The oleaginous yeast Rhodosporidium toruloides can co-utilize complex carbon sources and grow robustly on lignocellulosic hydrolysates. This makes it an attractive host for heterologous production of valuable bioproducts at high titers from low-cost, deconstructed biomass in an economically and environmentally sustainable manner. Researchers with the Joint BioEnergy Institute demonstrated this capability by engineering R. toruloides to produce the polyketide triacetic acid lactone (TAL) directly from unfiltered hydrolysate deconstructed from biomass with minimal unit process operations.

The Impact

Lignocellulosic biofuel production can be more profitable when produced alongside valuable bioproducts such as TAL. The yeast R. toruloides is a versatile host for producing a range of biofuels and bioproducts that now includes TAL. Many steps involved in deconstructing biomass into fermentable substrate can be combined into a distinct operation and directly fed to engineered R. toruloides cultures for subsequent valorization into TAL in a cost-effective manner. This work advances economical production of biofuels and bioproducts.

Summary

The gene 2-pyrone synthase was introduced into R. toruloides, enabling it to produce TAL from hydrolysates of lignocellulosic sorghum feedstocks that were either field dried or ensiled (i.e., partially fermented). The filtered hydrolysates from ensiled sorghum produced higher TAL titers than those derived from dried sorghum, likely due to the substantial organic acids produced during ensiling.

The organic acids in ensiled biomass can be used for direct synthesis of ionic liquids within the biomass pretreatment process. This enabled consolidation of unit operations of in situ ionic liquid synthesis, pretreatment, saccharification, and fermentation into a one-pot, separations-free process. A demonstration of the single-pot concept produced 3.9 g/L TAL from unfiltered hydrolysate.

TAL can be chemically converted to sorbic acid, fungicides, and valuable chemicals such as resorcinol, phloroglucinol, and 1,3,5 trihydroxybenezene. Other applications include polymers, plasticizers, organic synthesis, adhesives, and emulsifiers.

Principal Investigator

John Gladden

Lawrence Berkeley National Laboratory

jmgladden@lbl.gov

BER Program Manager

Shing Kwok

U.S. Department of Energy, Biological and Environmental Research (SC-33)

Biological Systems Science Division

shing.kwok@science.doe.gov

Funding

This material is based upon work supporting the Joint BioEnergy Institute through the U.S. Department of Energy, Office of Science, Biological and Environmental Research program, through contract DE-AC02-05CH11231 between Lawrence Berkeley National Laboratory and the U.S. Department of Energy. This material is also based upon work supporting the LBNL Advanced Biofuels and Bioproducts Process Development Unit, through the Bioenergy Technology Office within the DOE Office of Energy Efficiency and Renewable Energy.

References

Otoupal, P., et al. 2022. “Advanced One-Pot Deconstruction and Valorization of Lignocellulosic Biomass into Triacetic Acid Lactone Using Rhodosporidium toruloides,” Microbial Cell Factories 21, 254. DOI:10.1186/s12934-022-01977-0.