08/25/2021

Assessing the Production Cost and Carbon Footprint of a Promising Aviation Biofuel

Biomass-derived DMCO has the potential to serve as a low-carbon, high-performance jet fuel blendstock

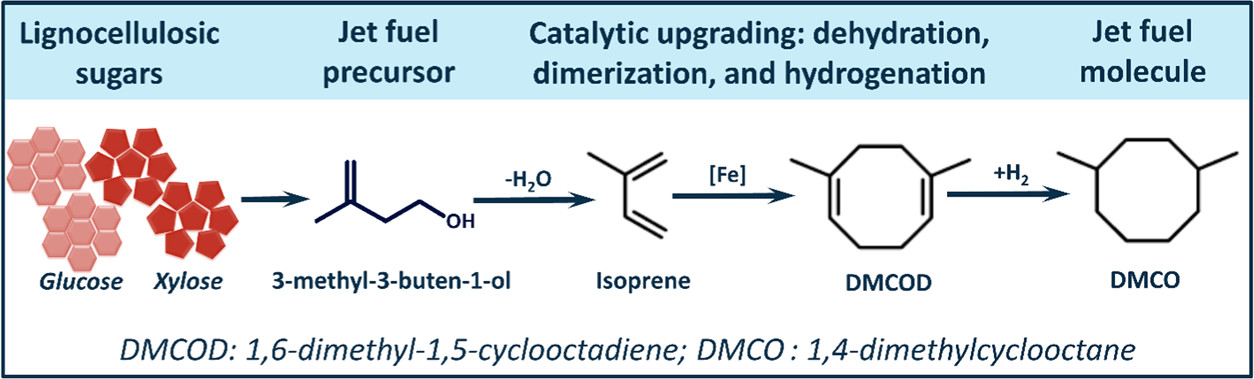

From biomass to jet fuel. Overview of 1,4-dimethylcyclooctane (DMCO) synthesis from biomass-derived glucose and xylose.

[Reprinted from Baral, N.R., et al. 2021 under a Creative Commons license (CC BY-NC-ND 4.0).]

The Science

Energy-dense, renewable aviation fuels—made from biobased sources instead of petroleum—play an important role in decarbonizing the aviation industry. Scientists have developed numerous routes to produce biobased blendstocks suitable for use in Jet A, a commonly used commercial aviation fuel. One such promising fuel is 1,4-dimethylcyclooctane (DMCO), which is derived from sustainable lignocellulosic biomass. DMCO can be produced from isoprenol through a multistep upgrading process. To assess DMCO’s potential as a blendstock, researchers at the Joint BioEnergy Institute (JBEI) conducted a detailed technoeconomic analysis and lifecycle greenhouse gas (GHG) inventory of DMCO production from isoprenol using sorghum as a feedstock.

The Impact

DMCO, with a volumetric net heat of combustion up to 9.2% higher than Jet A, has the potential to serve as a low-carbon, high-performance jet fuel blendstock that may enable paraffinic biojet fuels to operate without aromatic compounds. Results indicate that although DMCO is unlikely to be the lowest-cost biojet fuel available, it serves a potentially unique purpose among sustainable aviation fuel blendstocks. Provided further scale-up, process intensification, and system optimization to reduce costs and emissions, DMCO may be important in enabling a 100% renewable aviation sector.

Summary

JBEI researchers developed detailed process configurations for DMCO production to estimate the fuel’s minimum selling price and lifecycle GHG footprint. The study considered three different hydrogenation catalysts—10%Pt/C, Raney nickel, and 10%Pd/C—and two bioconversion pathways—mevalonic acid pathway (MAP) and 5-methyl erythritol phosphate pathway (MEP). The platinum-based catalyst offered the lowest production cost and GHG footprint of $9.0/L Jet-Aeq and 61.4 gCO2e/MJ, given the current state of technology. However, when the supply chain and process were optimized, hydrogenation with the Raney nickel catalyst was preferable, resulting in a $1.5/L Jet-Aeq cost and 18.3 gCO2e/MJ GHG footprint with sorghum as the feedstock. Dramatic improvements are required to achieve this price, including higher sorghum yields and increased conversion at different points in the process—from the breakdown of biomass to sugars, to biological conversion of sugars to isoprenol, and final conversion to DMCO. All modeling was done in SuperProDesigner, and the lifecycle GHG inventory used JBEI’s previously developed BioC2G model.

Principal Investigator

Corinne D. Scown

Lawrenece Berkeley National Laboratory

cdscown@lbl.gov

BER Program Manager

Kent Peters

U.S. Department of Energy, Biological and Environmental Research (SC-33)

Biological Systems Science Division

kent.peters@science.doe.gov

U.S. Department of Energy, Biological and Environmental Research (SC-33)

Biological Systems Science Division

shing.kwok@science.doe.gov

Funding

This work is part of the Joint BioEnergy Institute, a DOE Bioenergy Research Center supported by the Genomic Science program of the Office of Biological and Environmental Research, within the DOE Office of Science, through contract DE-AC02-05CH11231 between Lawrence Berkeley National Laboratory and DOE. This study was also supported by the Bioenergy Technologies Office within the DOE Office of Energy Efficiency and Renewable Energy. B.G.H. acknowledges funding from the Office of Naval Research Bioengineering and Biomanufacturing Program.

References

Baral, N.R. et al. “Production Cost and Carbon Footprint of Biomass-Derived Dimethylcyclooctane as a High-Performance Jet Fuel Blendstock.” ACS Sustainable Chemical Engineering 9(35), 11872–11882 (2021). [DOI:10.1021/acssuschemeng.1c03772]