The Center for Bioenergy Innovation (CBI), led by Oak Ridge National Laboratory, is pursuing high-impact scientific and technological innovations to create dedicated bioenergy crops (e.g., poplar and switchgrass) as a cost-efficient substitute for petroleum-based fuels and products. Through basic science research on dedicated bioenergy crops and a suite of engineered microbes, CBI researchers are developing high-yielding, process-advantaged, sustainable plant biofeedstocks and designing economic and efficient bioprocessing approaches using microbes that produce biofuels and bioproducts, including hydrocarbons for jet fuel and chemical feedstocks for plastics precursors.

The Center for Bioenergy Innovation (CBI), led by Oak Ridge National Laboratory, is pursuing high-impact scientific and technological innovations to create dedicated bioenergy crops (e.g., poplar and switchgrass) as a cost-efficient substitute for petroleum-based fuels and products. Through basic science research on dedicated bioenergy crops and a suite of engineered microbes, CBI researchers are developing high-yielding, process-advantaged, sustainable plant biofeedstocks and designing economic and efficient bioprocessing approaches using microbes that produce biofuels and bioproducts, including hydrocarbons for jet fuel and chemical feedstocks for plastics precursors.

Specifically, the CBI team is accelerating progress toward using natural genetic variants found in plants to improve growth, yield, composition, and sustainability traits to lower feedstock costs and improve year-round feedstock supplies. Additionally, CBI is developing consolidated bioprocessing with cotreatment (C-CBP) as a process to simultaneously digest plant biomass and convert it to select biofuels and bioproducts. Advancements in C-CBP combine multiple approaches and tools to overcome industrially relevant barriers to using microbes in biomass deconstruction and conversion, including cotreatments such as brief milling during deconstruction.

Feedstock Optimization. Naturally varying poplar genotypes are grown in a greenhouse (shown) and in field trials to measure important phenotypes of growth, composition, and sustainability. [Courtesy CBI]

Ultimately, CBI aims to:

- Create high-yielding bioenergy crops that display uniform productivity and increased sustainability by harnessing natural diversity via genomic selection in two perennial feedstocks—poplar and switchgrass.

- Reduce the cost of CBP technologies that convert carbohydrates to fermentation intermediates that can be catalytically upgraded to sustainable aviation fuels (SAFs).

- Utilize plant cell wall components more completely, specifically lignin, to improve production of fuels, coproduct chemicals, and novel materials.

Research Focus Areas

CBI’s feedstocks-to-fuels process encompasses several innovation targets that will enable the future bioeconomy. During feedstock and process development, CBI will address fundamental and enabling science questions using systems and synthetic biology and advanced computational approaches to improve process-advantaged plant traits, microbial biorefining, and robust catalysts.

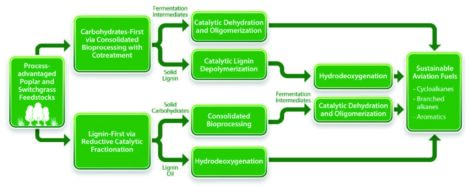

Feedstocks to Fuels. CBI’s process follows either one of two conversion paths from sustainable, process-advantaged feedstocks to sustainable aviation fuels (SAFs). In one path (top), carbon-efficient conversion occurs via consolidated bioprocessing (CBP) with cotreatment in which carbohydrates are converted first. Fermentation intermediates are then catalytically upgraded, and lignin-enriched residuals are deconstructed and deoxygenated into SAF blendstocks. In an alternate path (bottom), carbon-efficient conversion occurs via a reductive catalytic fractionation (RCF) process in which lignin in whole biomass is converted to RCF oil that is then deoxygenated to SAF blendstocks. Carbohydrate-enriched residuals are subsequently deconstructed and converted to fermentation intermediates via CBP and then catalytically upgraded into SAF blendstocks. [Courtesy CBI]

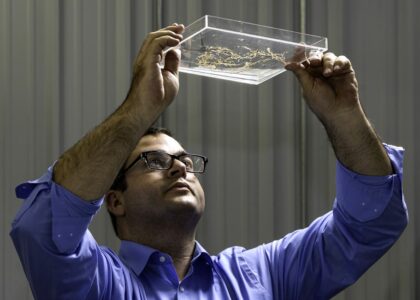

Imaging Feedstock Root Growth. A CBI researcher examines switchgrass root architecture prior to collecting a digital image that is later analyzed to extract and measure important root traits that impact plant biomass yield and sustainability. [Courtesy CBI]

Fundamental and broadly enabling science questions that arise during development of nonmodel CBP microbes are also being addressed. CBI researchers use adaptive laboratory evolution and CRISPR-based genomic editing tools to rapidly domesticate these microorganisms and to describe the foundational science of microbial biomass deconstruction processes that are applicable to a wide range of biofeedstocks and relevant to the new bioeconomy. C-CBP microbes have recently achieved near-total carbohydrate solubilization of poplar and switchgrass biomass. Industrially relevant C-CBP will be developed for the feedstock-to-fuels process by characterizing, designing, and optimizing metabolic performance to improve production of targeted intermediates.

Carbon-Efficient Lignin Conversion to Biofuels and Bioproducts. CBI is developing new processes and technologies to transform lignin-rich residues into biofuels and bioproducts, including chemical feedstocks such as propanol guaiacol and propanol catechol. Researchers use cutting-edge tools like nuclear magnetic resonance to study natural variation in plant cell wall biopolymers, like lignin, and identify target structural modifications that enhance lignin extraction for conversion to specialty biofuels including SAFs. Lignin is being selectively removed from plant cell walls using reductive catalytic fractionation (RCF), a process that solubilizes and partially depolymerizes lignin by targeting its carbon-oxygen bonds. CBI researchers aim to use the resulting lignin oils as upgradable intermediates for SAF.

In addition, researchers are employing biological funneling to produce chemical precursors for value-added biomaterials. In this process, microbial biocatalysts are designed to exhibit ligninolytic aromatic-catabolic activities, funnel heterogeneous aromatic monomers to central aromatic intermediates, and produce target chemical feedstocks from lignin via atom-efficient transformations. CBI targets three lignin-derived products (cis,cis-muconic acid; 2-pyrone-4,6-dicarboxylic acid; and α-ketoadipate) that can be cost effectively converted into precursors for commodity polymers such as adipic and terephthalic acids.

Microbial Engineering. A CBI researcher uses genomic editing tools to rapidly domesticate microorganisms for improved production of biofuels and bioproducts while also providing a roadmap for gene-to-trait discovery in nonmodel organisms. [Courtesy CBI]

Industry Interactions

CBI seeks to form important industrial relationships, disseminate research results, gain feedback on industrial bottlenecks and concerns, and generate information about commercial opportunities including collaborations. Significant interactions have occurred between CBI and various companies including DSM, Forage Genetics International, Gevo, Commercial Aviation Alternative Fuels Initiative, Chevron, LanzaJet, and Phenotype Screening Corporation. For example, together with DOE’s Joint Genome Institute and LanzaTech, CBI released the genome sequences of more than 200 industrial Clostridia species.

Intellectual property (IP) is disclosed to CBI’s Commercialization Council, which consists of technology transfer representatives from each CBI partner institution. The council reviews the technical merit and commercial potential of CBI-funded inventions and shares licensing leads. Each owner institution protects its CBI inventions according to that institution’s standard practices and coordinates any joint IP. CBI and the other BRCs also jointly market industrial interactions and key meetings. In fiscal year 2021, CBI partners produced 21 invention disclosures, 14 patent applications, and 4 issued patents.

Education and Outreach

CBI offers interdisciplinary research opportunities for graduate students, postdoctoral researchers, and visiting scientists and seeks to broaden public understanding of bioenergy and the pipeline of future bioeconomy workers. For example, the “Farming for Fuels” hands-on and distance-learning programs with hubs at science centers in 14 states, built in collaboration with the Creative Discovery Museum in Chattanooga, Tenn., have reached more than 330,000 students, parents, and teachers in 13 years. The programs incorporate Next Generation Science Standards (K-12 science content standards) and are available at learnbioenergy.org. In 2021, lessons were downloaded by approximately 20,000 users. The ongoing program is self-sustaining with direct costs only in training, distance learning, and curricula development.

In addition, CBI collaborated with various partners to establish a diversity, equity, inclusion, and accessibility (DEIA) task force. The task force produced a comprehensive DEIA plan consisting of actionable items to improve CBI’s diversity, incorporate training opportunities and enable career advancement, make meaningful impacts in the community through outreach, and ultimately enable and support CBI’s scientific endeavors. It also developed, distributed, and analyzed baseline results from a demographic and cultural climate survey with input from several CBI partner institutions to identify specific objectives and measure CBI’s DEIA efforts and perception for the next 5 years. CBI has added the historically black University of Maryland Eastern Shore as a research partner in feedstock sustainability.

CBI Partners

- Oak Ridge National Laboratory (Oak Ridge, Tennessee; lead institution)

- Brookhaven National Laboratory (Upton, New York)

- Dartmouth College (Hanover, New Hampshire)

- Institut National de Recherche Agronomique (Montpellier, France)

- Massachusetts Institute of Technology (Cambridge)

- National Renewable Energy Laboratory (Golden, Colorado)

- Poplar Innovations, Inc.

- The Pennsylvania State University (State College)

- University of California—Davis

- University of California—San Diego

- University of Georgia (Athens)

- University of Maryland Eastern Shore (Princess Anne, Maryland)

- University of Tennessee—Knoxville

- University of Virginia (Charlottesville, Virginia)

- University of Wisconsin—Madison

- Washington State University (Pullman, Washington)

CBI Contacts

- https://cbi.ornl.gov/

- Oak Ridge National Laboratory

Oak Ridge, TN 37830 - Gerald Tuskan, tuskanga@ornl.gov