Visualization of Solvent Disruption of Biomass and Biomembrane Structures in the Production of Advanced Biofuels and Bioproducts

Authors:

Brian H. Davison1* (davisonbh@ornl.gov), Barbara Evans1, Arthur J. Ragauskas1,2, Micholas Dean Smith1,2, Haden L. Scott1, Sai Venkatesh Pingali1, Hugh M. O’Neill1, Loukas Petridis1, Luna Liang2, Riddhi Shah2, Xianzhi Meng2, Yunxuan Wang2, Yunqiao Pu1, and Jeremy C. Smith1,2

Institutions:

1Oak Ridge National Laboratory (ORNL); and 2University of Tennessee–Knoxville

URLs:

Goals

The Solvent Disruption of Biomass and Biomembranes Science Focus Area (SFA) provides fundamental knowledge about how solvents alter the structures of plant cell walls and microbial membranes. The project’s overarching hypothesis is that knowledge of partitioning or binding of the solvent from the bulk phase to biomass or biomembranes can help predict maximal or minimal disruption. Solvents disrupt biological structures comprising amphiphilic molecules and polymers (e.g., membranes and biomass). Determining common biophysical principles of solvent disruption will lead to new understandings of how solvents affect the relevant structures. This information will help determine the ultimate microbial limits in tolerating specific solvents, as well as the eventual design of co-solvents best suited for pretreatment. The SFA will integrate the power of world-class neutron scattering capabilities and leadership-class supercomputing facilities available at ORNL. These capabilities are complemented by expertise in biodeuteration and biomembranes at ORNL, plant cell wall chemistry at the University of Tennessee, and interpreting small-angle neutron scattering (SANS) data at the University of Cincinnati.

Abstract

A sustainable bioeconomy will undoubtably rely on the efficient production of lignocellulosic biofuels that can be combusted directly in automobile engines or catalytically upgraded to long-chain hydrocarbons for use as diesel and aviation fuels. Plant cell wall structure of biomass is an intricate design of several carbohydrate polymers encased in the hydrophobic lignin polymer to protect against degradation. The recalcitrance to deconstruction of lignocellulosic biomass due to the complex physicochemical structure of plant cell walls is a challenge in biological-based biorefinery systems due to the complex physicochemical structure of plant cell walls. Pretreatment and genetic modification are two approaches in biomass conversion that have succeeded in modifying the structure of lignocellulose to enable better enzymatic deconstruction. However, the structural differences among pretreatment-solubilized biomass biopolymers have not been extensively investigated. The SFA’s goal is to understand the molecular-level mechanism which drive efficient biomass deconstruction. ORNL scientists have reported direct experimental and computational evidence of physical chemical principles underlying pretreatment. Here, the team will discuss the use of molecular dynamics (MD) simulations, experimental pretreatments with acids and with acidified solvents combine the scattering measurement to elucidate structural changes in the three key biomass lymers (cellulose, hemicellulose, and lignin). This will be illustrated by several examples.

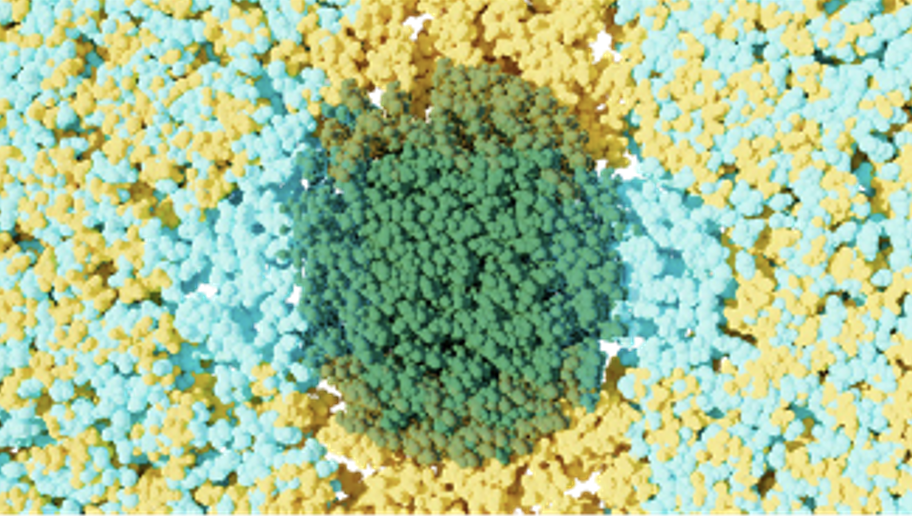

Researchers determined that solvent mixtures with both hydrophilic and hydrophobic interactions are key for efficient deconstruction of biomass as revealed by neutron scattering and molecular simulation. The team elucidated the effect of tetrahydrofuran (THF)-water pretreatment on the nanoscale architecture of biomass and the role the co-solvents play in solubilizing lignin and cellulose (Pingali et al. 2020). In situ SANS determined temperature-dependent changes in biomass morphology; whereas lignin dissociates over a wide temperature range (>25°C), cellulose disruption occurs only above 150°C. SANS with contrast variation and MD simulations provided direct evidence for the formation of THF-rich nanoclusters (~0.5 nm) on the nonpolar cellulose surfaces and on hydrophobic lignin, and equivalent water-rich nanoclusters on polar cellulose surfaces.

In another example, three organosolv pretreatment systems—ethanol (EtOH), tetrahydrofuran, and γ-valerolactone, in dilute acidic aqueous—were used on wild-type and two transgenic switchgrasses with altered lignin. All organosolv pretreatments caused a significant reduction in the molecular weights of lignins particularly, and up to ~90% decrease was observed in EtOH pretreated lignin compared to untreated lignin. A correspondence was found between the molecular weight reduction of lignin molecules in the experiments and the number of hydrogen bonds between lignin and the organic solvents as calculated in the MD simulation, suggesting a connection between the depolymerization of lignin and its ability to hydrogen bond with the organic solvents.

To understand the role of noncellulosic switchgrass polymers on the overall efficiency of pretreatment, the structural evolution of the noncellulosic polymers of the plant cell wall was investigated during dilute acid pretreatment by employing in situ SANS on various polymer fractions from switchgrass (Yang et al. 2021). In this study, researchers observed real-time structural changes not possible to observe by any other technique. These interpretations were consistent with MD simulations. These results suggest that not only lignin but also hemicellulose can form aggregate particles within plant cell walls during pretreatment. These concepts can be employed to tune pretreatment technologies that maximize deconstruction of biomass and facilitate the separation of its components for upgrading to energy and materials.

Image

Figure. Local demixing of water (blue) and tetrahydrofuran (THF; yellow) on the surfaces of cellulose (green). Water and THF are mixed in the bulk away from the cellulose. Courtesy Oak Ridge National Laboratory.

References

Liang, L., et al. 2022. “Chemical and Morphological Structure of Transgenic Switchgrass Organosolv Lignin Extracted by Ethanol, Tetrahydrofuran, and γ-Valerolactone Pretreatments,” ACS Sustainable Chemistry and Engineering 10(28), 9041–52. DOI:10.1021/acssuschemeng.2c00948.

Pingali, S. V., et al. 2020. “Deconstruction of Biomass Enabled by Local Demixing of Cosolvents at Cellulose and Lignin Surfaces,” Proceedings of the National Academy of Sciences of the United States of America 117(29), 16776–81. DOI:10.1073/pnas.1922883117.

Yang, Z., et al. 2021. “Structural Reorganization of Noncellulosic Polymers Observed In Situ During Dilute Acid Pretreatment by Small-Angle Neutron Scattering,” ACS Sustainable Chemistry and Engineering 10(1), 314–22. DOI:10.1021/acssuschemeng.1c06276.

Funding Information

This research is supported by the U.S. Department of Energy (DOE), Office of Science, through the Genomic Science program, Biological and Environmental Research (BER) Program, under FWP ERKP752. Oak Ridge National Laboratory (ORNL) is managed by UT-Battelle, LLC for the U.S. DOE under Contract no. DE-AC05-00OR22725. It used neutron scattering resources at the High Flux Isotope Reactor, a DOE Office of Science, Scientific User Facility operated by the ORNL. SAXS measurements were performed at the LiX beamline of the National Synchrotron Light Source II, a U.S. DOE Office of Science User Facility operated by Brookhaven National Laboratory under Contract No. DE-SC0012704.